LUXQ Precession Vortex Flow Meter

application:Flow measurement of natural gas and coal-based gas in oilfield, coal mine, metallurgy, chemical industry, etc.

medium:

Various gas flows

LUXQ series intelligent precession vortex flowmeter is a new type of gas flowmeter developed by our company with domestic leading level. The flowmeter integrates flow, temperature and pressure detection functions, and can automatically compensate for temperature, pressure and compression factors.

LUXQ series intelligent precession vortex flowmeter can be widely used in industries such as petroleum, chemical, electric power, metallurgy, urban gas supply to measure various gas flows, which is the first choice for oil and gas transmission and metering and trade measurement.

LUXQ series intelligent precession vortex flowmeter can be widely used in industries such as petroleum, chemical, electric power, metallurgy, urban gas supply to measure various gas flows, which is the first choice for oil and gas transmission and metering and trade measurement.

Detailed introduction

Ⅰ.Features■No mechanical movable parts, not easy to corrode, stable and reliable, long life, no special maintenance for long-term operation;

■Use 16-bit computer chip, high integration, small volume, good performance, strong machine function;

■Intelligent type flowmeter integrates flow probe, microprocessor, pressure and temperature sensor. It uses built-in combination to make the structure more compact. It can directly measure the flow, pressure and temperature of the fluid, and automatically track the compensation and compression factor correction in real time.

■Use double detection technology, it can effectively improve the detection signal strength and suppress the interference caused by pipe vibration;

■Use domestic leading intelligent aseismic technology, effectively suppressing interference signals caused by vibration and pressure fluctuations;

■Use Chinese character dot matrix display, the display has many digits, the reading is intuitive and convenient, and can directly display the volume flow under working condition;

■Volume flow, total amount, and medium pressure, temperature and other parameters under standard condition;

■Use EEPROM technology, easy to set up the parameters, can be saved permanently, and can save historical data up to one year ;

■The converter can output frequency pulse, 4~20mA analog signal, and has RS485 interface, which can directly communicate with the microcomputer. The transmission distance can reach 1.2km;

■Multiple physical parameter alarm output, which can be selected by the user;

■The meter head can rotate by 350 degrees, which is easy to install and use;

Ⅱ. Working Principle

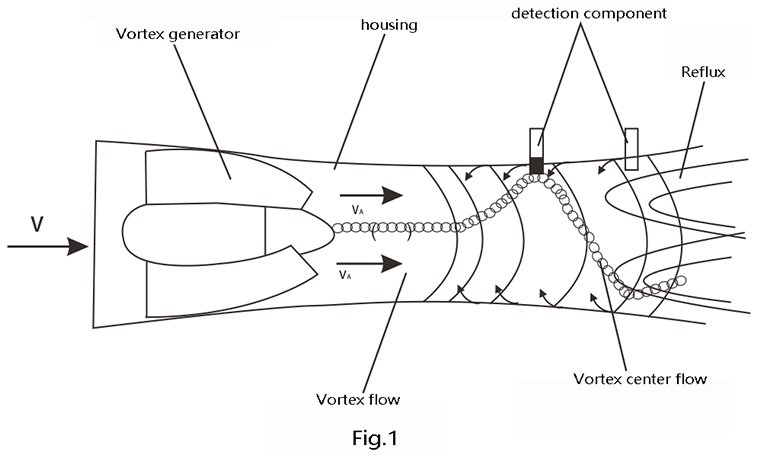

The flow sensor flow profile is similar to that of a venturi tube (Fig. 1). A set of spiral guide vanes are placed on the inlet side. When the fluid enters the flow sensor, the guide vanes forces the fluid to produce a sharp vortex flow. During the diffusion section, the vortex flow is subjected to reflux and begins to make a second rotation to form a gyro-type eddy current precession phenomenon. The precession frequency is proportional to the flow and is not affected by the physical properties and density of the fluid. The detection component measures the secondary rotation precession frequency of the fluid to obtain good linearity in a wide flow range. The signal is amplified, filtered, and shaped by a preamplifier into a pulse signal proportional to the flow rate, then,it is sent to the microprocessor for integration calculation together with the detection signals such as temperature and pressure, and finally displays the measurement results (instantaneous flow, accumulated flow and temperature, pressure data) on the LCD.

Ⅲ.Flowmeter selection

Ⅳ.Flowmeter Dimensions and Installation Dimensions

The external dimensions of the flowmeter are shown in Figure 3. The unmarked dimensions in the figure are listed in Table 1. The flowmeter use flange connection and implement the GB/T9112~9113-2000 standard.

Ⅴ.Installation Precautions

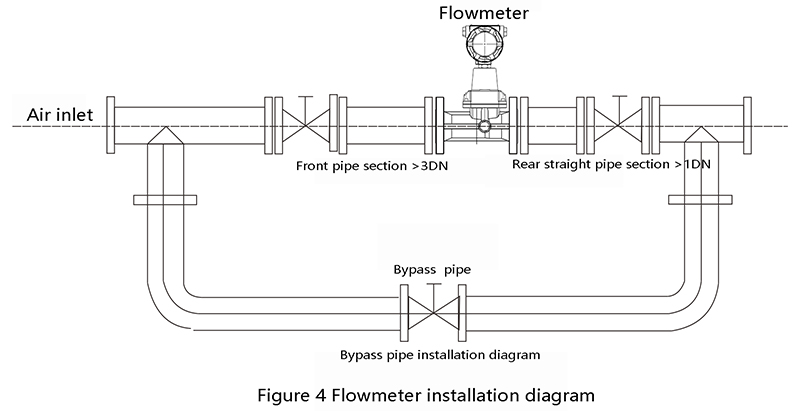

1. The sensor can be installed in the vertical, horizontal or any inclined position according to the flow direction mark;

2. When the pipe is long or close to the vibration source, support should be installed on the upstream and downstream of the flowmeter to eliminate the influence of pipe vibration;

3. The installation location of the sensor shall have sufficient space to facilitate the inspection and maintenance of the flowmeter and meet the environmental requirements of the flowmeter;

4. Avoid interference from strong external magnetic fields;

5. When installing and using outdoors, there shall be cover to avoid sun exposure and rain erosion, which will affect the service life of the meter;

6. When testing the pipe, pay attention to the pressure measurement range of the pressure sensor configured by the intelligent flowmeter to avoid overpressure and damage the pressure sensor;

7.Pay attention to the impact of installation stress, the upstream and downstream pipe installed in the flowmeter should be coaxial, otherwise it will produce shear stress. The position of the flowmeter should take into account the thickness of the gasket or to install an elastic expansion joint on the downstream side;

8. Before installing the flowmeter, remove the welding slag and other debris;

9. When the machine is in operation, the upper and lower valves of the flowmeter should be slowly opened to prevent the instantaneous airflow from damaging spiral flow generator;

10. When the flowmeter needs to transmit signal remotely, it shall be connected to the external power supply (1224) VDC strictly according to the requirements of “Electrical Performance Index”. It is strictly forbidden to directly connect 220VAC or 380VAC power supply to the signal output port;

11. The user shall not change the wiring mode of the explosion-proof system and arbitrarily twist each output lead connector;

12. When the flowmeter is in operation, it is not allowed to open the back cover to change the meter parameters, otherwise it will affect the normal operation of the flowmeter;

13. Check the leakage at the flange of the flowmeter regularly.

Chinese

Chinese English

English

Current position:

Current position:

South China

South China