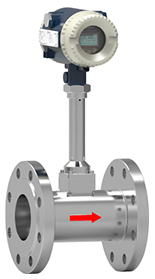

LUGB type Vortex Flowmeter

application:Steam, compressed air, coal gas, etc.

medium:

Measuring high-speed gas

LUGB type vortex flowmeter is a new type of flowmeter introduced by our company, the design of which is reasonable and the function is powerful, it also has linear correction function, reaching the world advanced level. The flowmeter adopts a high-resolution low-power full dot-matrix LCD display, which is clear and intuitive and it’s easy to operate. RS485 or HART communication can meet various needs of users; 12 kinds of compensation algorithms can almost satisfy all flow compensation calculations. Correction curve relying on external data and calibration method based on standard signal lead the trend of instrument calibration.

Detailed introduction

Ⅰ.Features■No moving components, long-term stabilization, structure is simple for easy installation and maintenance

■The output of the sensor is the pulse frequency, its frequency is linear with the actual flow rate of the fluid measured, it has no zero drift, and the performance is very stable. The structure is various in the form of pipeline and plug-in type flow sensors;

■The accuracy is high, the accuracy of measuring liquid is usually 11.0%, and the accuracy of measuring gas is ±1.5%;

■The measurement range is wide, and in the range of reynolds number is 2×104~7×106, it can reach 1:20;

■Low pressure loss(about 1 /4-1 /2 of the orifice flowmeter), which belongs to the energy-saving flow instrument;

■The installation method is changeful. It can be installed horizontally, vertically and at different angles according to different process pipelines;

■It adopts interference cancellation circuit and anti-vibration sensor head, so it has certain anti-environmental vibration performance;

■It adopts ultra-low-power single-chip microcomputer technology. For one 3V10Ah battery, can be used for more than 3 years;

■The nonlinearity of the meter coefficient is corrected by software to improve the measurement accuracy;

■Adopts EPROM to conduct power fail safeguard to the accumulative flow, and the effective protection time is more than 10 years;

Ⅱ.Product Classification

1. Clamp type vortex flowmeter

Small installation size, simple structure and low cost.

2. Flange type vortex flowmeter

Integrated flange structure, easy installation, and it is widely used in the measurement of flow of compressed air, saturated and superheated steam, natural gas and various medium.

3.Sanitation type vortex flowmeter

It is widely used in liquid and steam metering in food and pharmaceutical industries. It can also measure small particles, miscellaneous turbid liquids, and can be used as flow transmitter in automatic control systems.

Ⅲ. Product selection

| Model | Interpretation | ||||||

| LUGB | ¨ | ¨ | ¨ | ¨ | ¨ | ¨ | Vortex flowmeter |

| Connection mode | 1 | Flange connection(for full tube vortex flowmeter) | |||||

| 2 | Flange clamping(for full tube vortex flowmeter) | ||||||

| Measured medium | 1 | liquid | |||||

| 2 | general gas | ||||||

| 3 | compressed air | ||||||

| 4 | steam | ||||||

| inside nominal diameter | 00 | 15mm | |||||

| 01 | 20mm | ||||||

| 02 | 25mm | ||||||

| 03 | 32mm | ||||||

| 04 | 40mm | ||||||

| 05 | 50mm | ||||||

| 06 | 65mm | ||||||

| 08 | 80mm | ||||||

| 10 | 100mm | ||||||

| 12 | 125mm | ||||||

| 15 | 150mm | ||||||

| 20 | 200mm | ||||||

| 25 | 250mm | ||||||

| 30 | 300mm | ||||||

| Compensation | N | Uncompensated(suitable for volume flow measurement occasions) | |||||

| T | Temperature compensation(suitable for saturated steam) | ||||||

| P | Pressure compensation(suitable for saturated steam) | ||||||

| F | Temperature and pressure compensation((suitable for superheated steam and compressed air) | ||||||

| Output type | N | Sensor type:24VDC power supply, output three-wire pulse signal | |||||

| A | Transmitter type:24VDC power supply,Output current signal 4~20mA | ||||||

| B | Intelligent:Lithium battery power supply,status display(Dual power supply, pulse output optional) | ||||||

| C1 | Intelligent:24VDC power supply,status display、output 4-20mA(pulse output optional) | ||||||

| C2 | Intelligent:24VDC power supply,status display、output two-wire system 4-20mA HART communication、(pulse output optional) | ||||||

| C3 | Intelligent:24VDC power supply,status display、RS485 communication、(Dual power supply, pulse output optional) | ||||||

| accuracy class | 15 | 1.5 level | |||||

| 10 | 1.0 level | ||||||

| material quality | S | 304 stainless steel | |||||

| L | 316(L)stainless steel(Customized,long supply cycle) | ||||||

| Explosion-proof | N | Non-explosion-proof type | |||||

| E | Explosion-proof type,ExdIICT6 | ||||||

| Pressure grade | P | Actual pressure grade(customization for high pressure, long supply cycle) | |||||

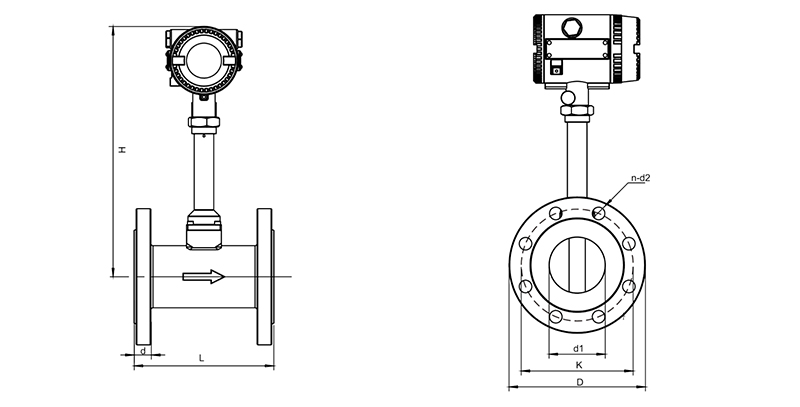

1. Installation size of full tube type turbine flow sensor, (Figure2)

2. Main physical dimension of the flange type flowmeter, (Figure 3)

Chinese

Chinese English

English

Current position:

Current position:

South China

South China