You have eight reasons to choose it!

● Without temperature and pressure compensation, the mass flow of gas is measured directly!

● High repeatability, high reliability, high stability and high accuracy!

● Wide range, maximum up to 1000:1

● Explosion protection and corrosion protection design, suitable for bad working conditions and dangerous occasions!

● High sensitivity, especially suitable for large diameter and low velocity flow measurement!

● The pressure loss is minimal and negligible!

● The utility model has the advantages of diverse structure, flexible installation, convenient loading and unloading and convenient use!

●Digital communication: RS232/485/MODBUS/HART digital communication protocol is optional.

Application range

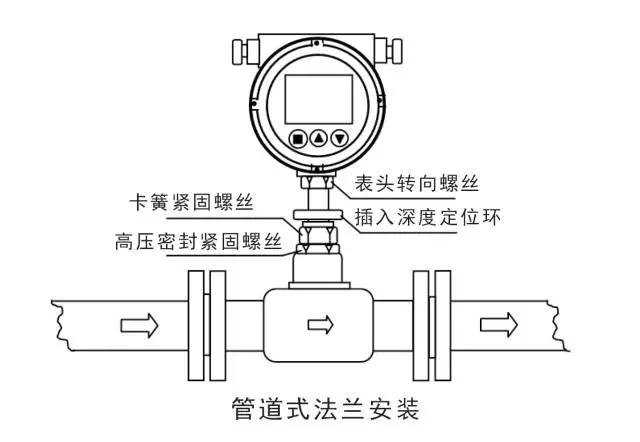

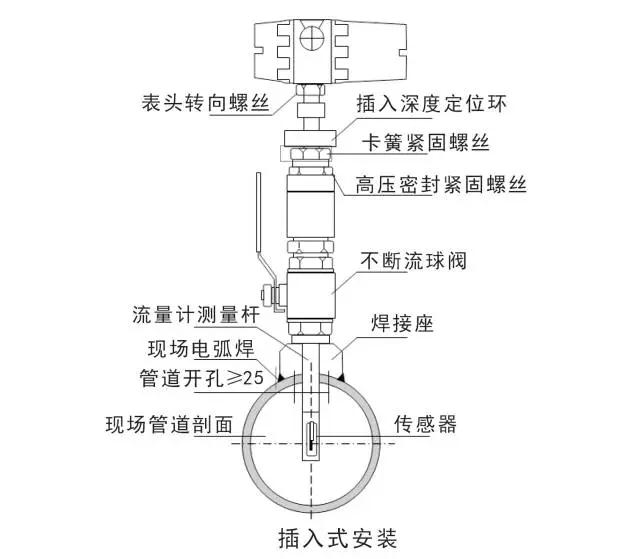

Thermal mass flowmeter is a kind of no pressure, temperature compensation, can easily detect flow measurement and monitoring instrument of mass flow in pipeline flow of air, natural gas, hydrogen, oxygen, chlorine, nitrogen, argon, ammonia, methane, gas, phosgene, flue gas and all kinds of chemical mixture, with accuracy high, fast response speed, wide measurement range; and because it has no moving parts, so it is stable and reliable, long service life. The structure of various types of flexible, with insert, line type, rectifier type, split and other forms; easy installation, screw mounted flange mounted, but also together with the continuous flow of dismantling equipment installation; protection, explosion-proof, corrosion proof design, make use of the flowmeter can adapt to harsh conditions and dangerous situations; minimal pressure loss, almost negligible.

t can be widely used in petroleum, chemical, metallurgy, electric power, water treatment, paper making, food, medicine, cement, textile, process control and gas flow measurement in various production and research institutions.

Application of thermal mass flowmeter in natural gas industry

Application of thermal mass flowmeter in natural gas industry

Application of thermal mass flowmeter in metallurgical industry

Installation form