Gas, that is, artificial gas, is a kind of gas, is the current city residents and many enterprises and institutions of the most important fuel. Some are also used as raw material for chemical products.

In the gas production, transmission and distribution of each link has a large number of gas meter, some for general surveillance, some for trade settlement, the measurement system for trade settlement, the national GB/T17167 standard specifies the accuracy requirements.

(1) characteristics of gas flow measurement;

A. fluid is low in static pressure and low in flow velocity, which allows low pressure loss. It is generally not allowed to increase the flow velocity by reducing the diameter of the pipe.

B. is high in humidity, and some objects carry a small amount of water at the bottom of the pipe to make a stratified flow.

C. some objects have high hydrogen content and small fluid density. When they are measured by vortex flowmeter, the signal is weak.

D. gas producer, coke oven and other gas produced in general with tar and other sticky things, and some also bring a certain amount of dust.

When the E. measuring point is located at the compressor outlet, there is a certain flow pulsation.

F. fluid belongs to flammable and explosive medium, and the instrument has explosion protection requirement.

G. from small to large, all kinds of pipe diameter.

H. minimum flow and maximum flow vary greatly.

I. systems used for trade settlement require high measurement accuracy; as a general monitoring and process control system, accuracy requirements are lower.

(2) the main contents stipulated by the national standards

In 2000 the State Bureau of quality and Technical Supervision issued the "urban GB/T18215.1 artificial gas main pipe flow measurement," the first part of the standard orifice plate throttling device, technical problems related to measurement of gas flow in the provisions for them:

Fluid requirements: "should be homogeneous and single-phase (or can be considered single-phase) fluid."".

Gas in the purification process are washed, so the general moisture content is saturated, the relative humidity is 100%.

The accuracy of measurement systems used in trade settlement should generally be better than level 2.5. The basic error limit is expressed as a percentage of the value.

The gas flow is defined as the dry part of the wet gas.

Measurement results are expressed in volume flow and converted to standard state. The definition of standard status, in addition to the general 101.325kPa, 20 degrees, but also take into account the tradition of the gas industry, but also desirable for the supply and demand sides of the negotiations of other temperature and humidity.

The throttling device adopts multiple parallel form.

When the flow pulsation, the following measures are proposed to measure the average number of.

A. uses attenuation measures on the line, and installs filters (consisting of containers and tube blocks).

B. instrument detector as far as possible from the pulse source.

C. uses the highest beta and delta P to reduce the pipe diameter at the measuring point.

D. pipe and instrument support are firmly installed.

E. two pressure differential pressure pipes are symmetrical in resistance.

3) the type and use of instruments

There are many kinds of flowmeters that can be used for measuring gas, but the ideal instrument for measuring gas flow is almost impossible to find. This is mainly determined by the characteristics of the gas. Due to the presence of viscous substances such as tar, rotating flowmeters are difficult to use. Because of the small density and low flow rate, the vortex flowmeter is difficult to use. The thermal flowmeter is not ideal because of the high moisture content and the change of gas composition. Finally, decades of differential pressure flow meters have been used as the main characters.

Orifice plate differential pressure flowmeter

A. orifice plate throttling device.

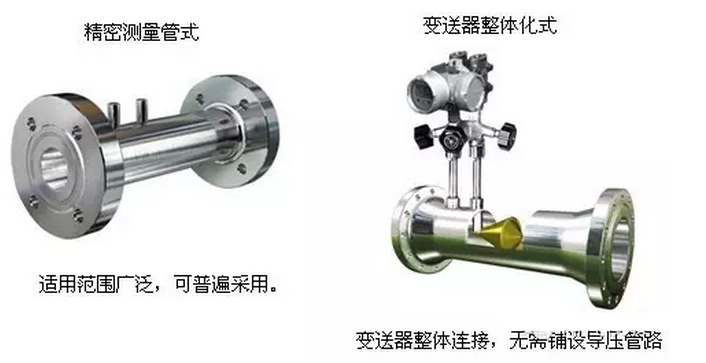

International GB/T18215 - 2000 specifies standard orifice plates. If the measuring point is dirty, use a replaceable orifice throttling device. Thus, under the condition of not stopping gas, the throttling parts can be cleaned, repaired and replaced. The typical structure of the orifice plate throttling device is shown in figure 3.18.

B. round hole plate.

The circular orifice plate is a special orifice designed for measuring the flow of soiled fluids. The opening is a part of a circle (round missing part), the diameter of which is 98% of the inner diameter of the pipe. The arc section of the opening shall be precisely positioned so as to be concentric with the pipe.

Uniform speed pipe differential pressure flowmeter.

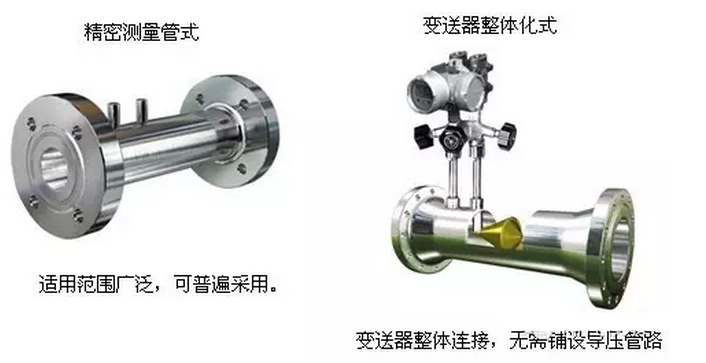

Standard orifice plate differential pressure flowmeter has a very important position in gas flow measurement, and has a long history of use. Because this method has lots of experimental data, design and processing have been standardized, as long as the standard for the design, processing, installation, testing and use, no real flow calibration is required, can achieve the required accuracy, so it is very convenient and widely applied. But in large diameter, a removable orifice plate throttling device price is considerable, so if the measurement data is only used for process monitoring, accuracy requirements are not high, so you can choose velocityequalizing tube differential pressure flowmeter.

The key to the success of the differential pressure flowmeter in the gas flow measurement is that the pressure pipe is not blocked by water droplets. The setting of Annubar shut-off valve products with mostly needle valve, smaller diameter and fluid in water by condensing into water, if not handled properly the needle valve or pipe slope is unreasonable, the droplets can be easily sealed channel.

Differential pressure average speed tube output differential pressure signal is usually very small. When the fluid is air at normal temperature and atmospheric pressure, if the flow rate is 10m/s, it can only reach 62.5Pa differential pressure [28]. In this way, a drop of water drops off the differential pressure transmission channel and is sufficient to counteract the differential pressure. Some manufacturers will be positive and negative pressure cut-off valve instead of larger straight through gate valve, in order to ensure the reliable use of instruments