Superheated steam is a relatively special medium, and generally speaking, steam means superheated steam. Superheated steam is a common power source, which is often used to drive the turbine to rotate, and then to drive the generator or centrifugal compressor. Superheated steam is obtained by heating the saturated steam without any liquid droplets or liquid fog, which belongs to the actual gas. The temperature and pressure parameters of superheated steam are two independent parameters, and their density should be determined by these two parameters. It can be checked by the superheated steam density meter. After a long distance transport of superheated steam, with the conditions (such as temperature and pressure) changes, especially in the superheat is not high, because the heat loss and the temperature decreases from overheating into saturated or supersaturated, become saturated steam or with droplets of saturated steam. The saturated steam suddenly decreases greatly, and the liquid will expand into superheated steam when it is adiabatic. Thus, the vapor liquid two phase flow medium will be formed.

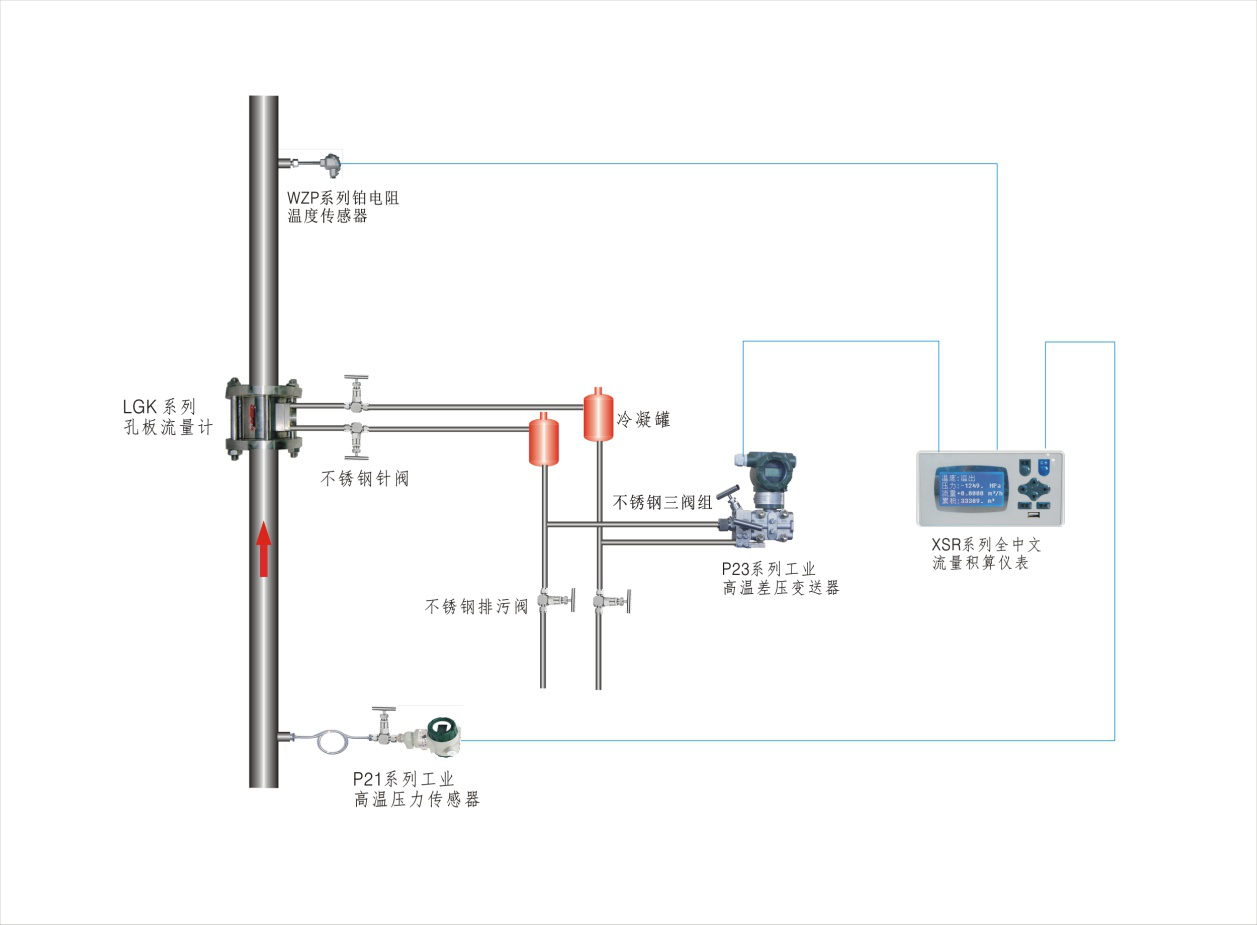

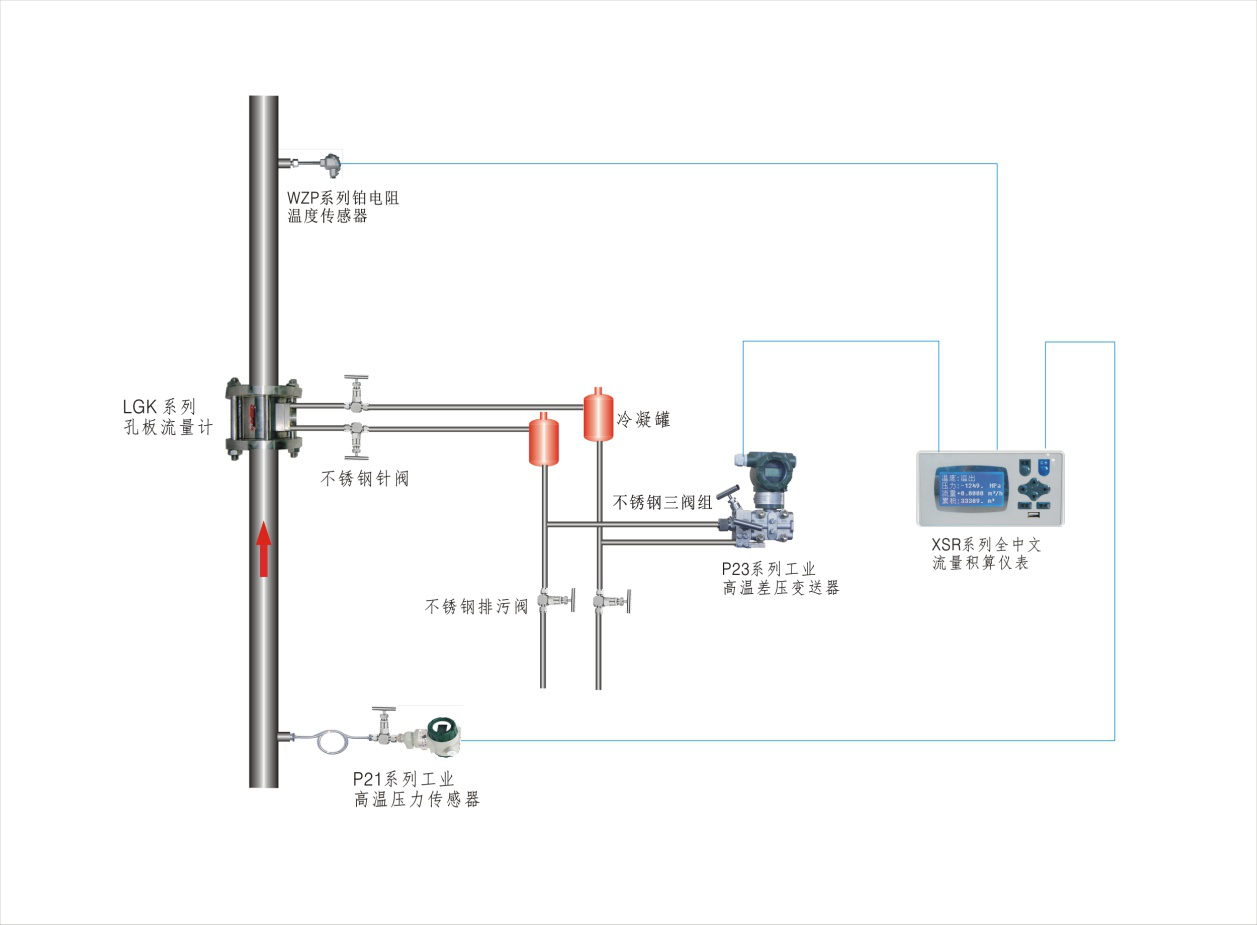

Schematic diagram of installation of superheated steam metering system

Measurement analysis

At present, the use of flow meters to measure steam flow, measuring medium refers to single-phase superheated steam or saturated steam. For the steam with constant phase change, there must be some inaccuracy in measurement. The solution to this problem is to keep the superheat steam, to reduce the moisture content of the steam, heat preservation measures such as strengthening the steam pipe, reducing the loss of pressure steam, in order to improve the accuracy of steam measurement. However, these methods can not completely solve the problem of inaccurate measurement of steam flow. The fundamental way to solve this problem is to develop a flow measuring instrument for measuring two-phase flow medium.

When the working state of the steam deviates from the design state, the flow indication will produce errors. It also affects the flow measurement, so the measurement of steam flow needs to be compensated, and the compensation factor is complicated because of the change of steam condition. Superheated steam density is determined by steam pressure and temperature of two different parameters, and the range of parameters, expressions of density is not the same, can not be expressed by the same formula, so cannot obtain the uniform density formula, only individual derived temperature and pressure compensation formula. In the range of temperature and pressure fluctuation, besides the temperature and pressure compensation, the expansion coefficient of gas should also be considered.

Regardless of the flowmeter testing the superheated steam flow in steam pressure fluctuation under the condition of pressure compensation measures must be taken, this is because in the flow equation, there are factors of steam density, working conditions and design conditions are not the same, the reading error will be generated, and the size of working pressure and design pressure deviation error, P >P will be negative error, otherwise there will be a positive error. Dry steam conditions is an important condition to accurate measurement of steam flow, currently being developed online steam quality measuring instrument, the degree of instrument applied to steam flow measurement and compensation system to be dry, will further improve the measurement accuracy. The following three measures should be taken at present:

(1) the pipeline conveying steam must have good insulation measures to prevent heat loss.

(2) in the steam pipeline to block water, at the lowest point of the pipeline and the instrument before the pipe should be equipped with traps, timely discharge condensate.

(3) boiler operation should avoid the phenomenon that the liquid level of drum is too high, so as to minimize the fluctuation of the load.

At present, there are more than 60 kinds of industrial flow meters, mainly including vortex street flowmeter, differential pressure type (orifice plate flow meter, uniform velocity pipe, bend pipe). V cone flowmeter, shunt type flowmeter, Annubar flowmeter, float type flowmeter. In history, there is no flow instrument suitable for any fluid, any range, any flow state, and any use condition. Any flow meter has its specific applicability and limitations. If the flow meter is not properly chosen, the flow must be measured incorrectly. But the flow measurement is a complicated technology, and many kinds of flow meters, even for a certain application, choose a suitable flow meter will become a highly technical work, need factors before making the final choice carefully and thoroughly consider and Quan Hengxu related measurement problems. Therefore, the correct choice of instrument is a key instrument in normal use, in the practical application, too much fault is due to instrument selection unreasonable, a detailed understanding of the field application of the operating conditions and the medium parameters, select the appropriate pressure, temperature, protection, explosion-proof grade and material structure, to ensure that the instrument can run in the best condition. Steam metering should consider 5 main factors in the selection of flow meter: measurement methods, performance requirements and instrument specifications, measured fluid characteristics, environmental conditions, economic conditions (purchase costs, installation costs, operating costs, maintenance costs, expenses check). In our practical work, whether it is used for industrial and mining enterprises heating centralized production, is the most used orifice plate flowmeter (nozzle) V cone flowmeter and vortex flowmeter, based on these two kinds of flowmeter as an example explained:

Differential pressure flowmeter

Differential pressure flowmeter is composed of a flow detection element is installed in the pipeline in (which produce a differential pressure device, referred to as the instrument of differential geometry), known fluid conditions and a meter and a pipeline to calculate the flow meter, a pressure device, pressure pipe and pressure gauge is composed of three parts. The orifice flow meter as the representative of the differential pressure flowmeter application has a long history, high degree of standardization, the application is widespread, may not be the real flow calibration, differential display instrument standardization and serialization and high level of generalization, the theory of high precision, wide application range and strong adaptability, low initial investment cost. But through practical application, it is found that the orifice flowmeter is also inadequate:

Many factors in the application (the design parameters and operating parameters are inconsistent, the upstream straight pipe length, orifice plate and pipe is not concentric orifice A surface contamination, sharp wear etc.) has great influence on the measurement accuracy, the measurement error increases, resulting in reduced accuracy. In particular, it is necessary to check the differential pressure transmitter regularly to ensure the accuracy of the zero point, and check the three way valve regularly to prevent the measurement error caused by the blockage.

The installation quantity is big, the more trouble, and the demand is high, need regular maintenance and cleaning of the larger workload.

It needs to be equipped with differential pressure transmitter, which increases the maintenance workload and needs to be deposited